Certifications

Quality policy ISO 9001:2015

We must work to ensure we carry out orders with high quality, service and support with short deliveries and to always be among the best in the industry.

This requires:

- That through clarity, accuracy, good accessibility and high literacy’s build a lasting trust of a “satisfied” customer.

- That we are responsive to customers’ and stakeholders’ requirements and needs, and promote open communication with the client.

- That we follow industry developments and changes within painting/blasting and its legislation.

- That we hire subcontractors and suppliers who meet our demands of “the right quality” and delivery.

- That our employees are trained to cope with their tasks and can take responsibility of a delegated organization.

- Actively work with continuous improvements

Environmental Policy ISO 14001:2015

The business is characterized by a sense of family that gives us good conditions for training and commitment of internal environmental issues.

Our ambition is to go beyond what environmental legislation requires, as well as other requirements that the business concerned.

We achieve this by:

- Prioritize the use of environmentally friendly materials wherever possible according to customer specification for commissioned work.

- Know and comply with laws and regulations within the work environment and external environmental field.

- Being responsive to our customers’ and other stakeholders’ environmental requirements.

- Continue to actively work with environmental improvement measures together with our suppliers.

- Develop employees’ environmental awareness and sense of responsibility for the environment.

- Create a safe, pleasant and stimulating working environment for our employees as well as safeguarding the remarks of safety inspections and other proposals through systematic environmental work.

- Work to ensure that a good business is by maintaining good communication with employees.

- Encourage all employees to take part of the applicable safety rules for providing a safe workplace.

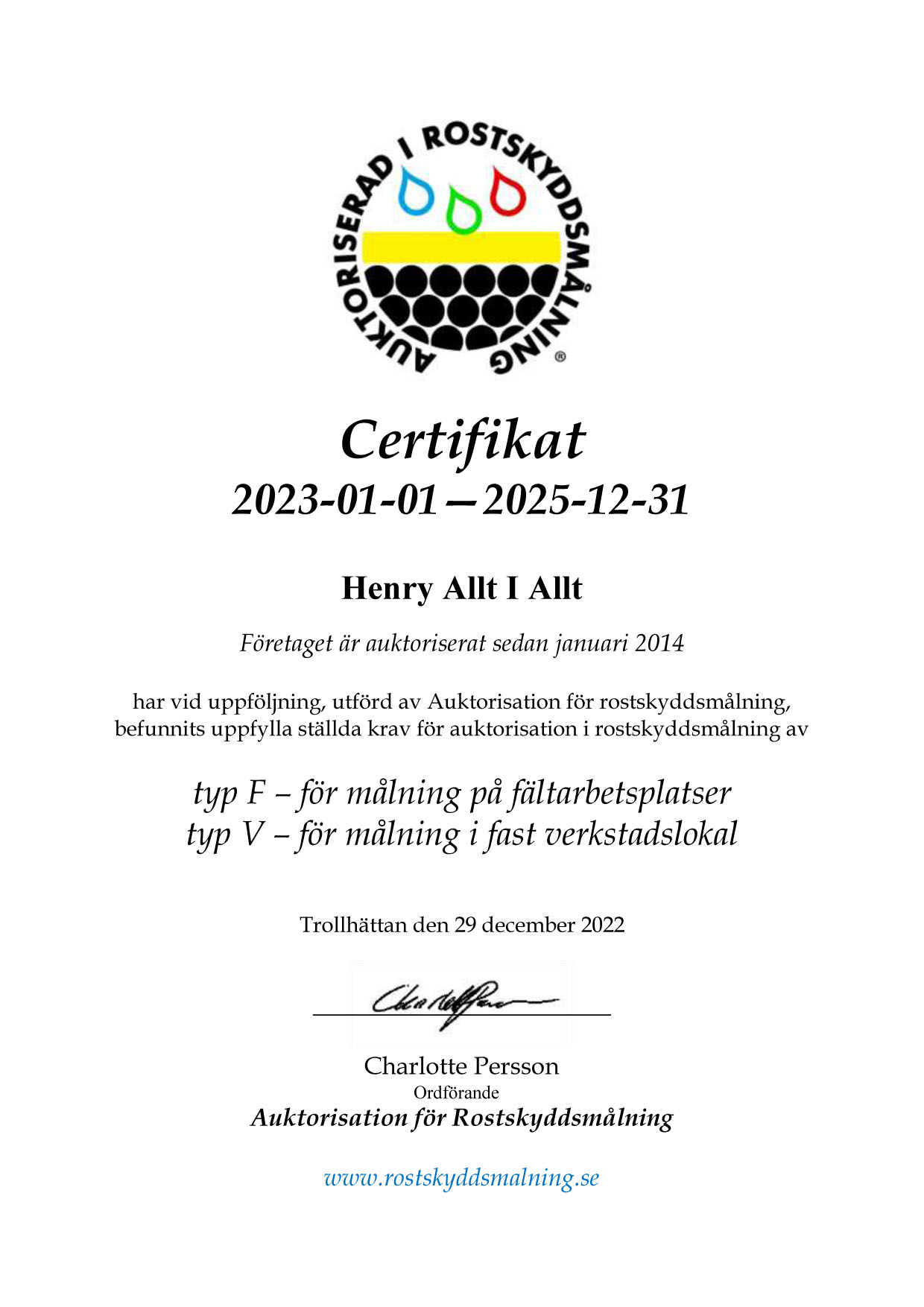

Authorization in rust protection painting

Metal destruction is a major problem in an industrial society. In metal destruction, rust is the most well known. Preventing rust can be done by surface treatment in different ways. Anti-rust painting is the most common one.

The work of anti-corrosion painting is controlled by metal, paint and finish. The result is a job performed correctly and professionally.

To ensure that there is good knowledge in the field of corrosion protection, there is a permit for Rust Protection Painting. The authorization is an industry association that works by maintaining high competence requirements for performers.

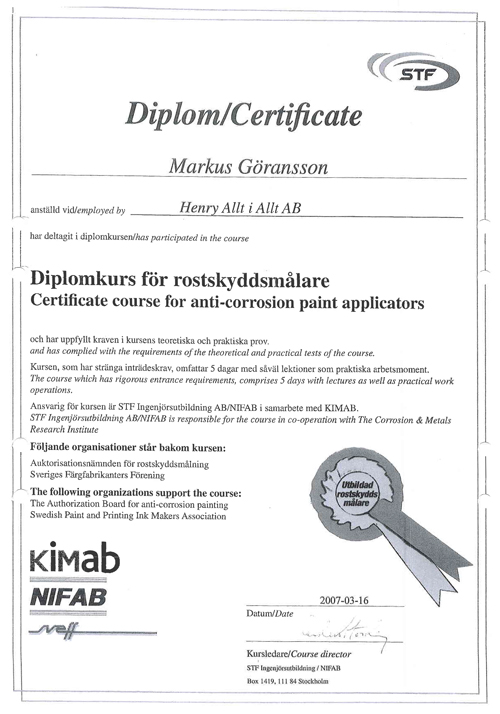

Surface and anti-corrosion painters

We meet the authority’s requirement to have at least 50% certified anti-corrosion painters at every workplace. In addition, at least 25% must have experience at least equivalent to the admission requirements for the Authorization Board’s approved education.

Surface and anti-corrosion painters

This ensures that the person who holds the certificate has undergone theoretical and practical training of at least 55 hours and is able to perform qualified pretreatment, blasting and rustproofing.

Theoretically

- Corrosion

- Impurities

- Control of the environment

- Degreasing, washing

- Cleaning with mechanical methods

- Blasting

- Inspection of surfaces before and after blasting

- Different types of corrosion paints

- Coating systems

- Color Data Sheet & Safety Data Sheet

- Planning of warehouses, rigging of temporary workplace

- Application of color

- Control of applied color

- Improvements

- Inspection

- Working environment

- External environment

Practically

- Beam blasting

- Machine grinding, brushing

- Painting with brush / roll

- High pressure spraying

- Conventional spraying

Knowledge control is conducted with a written exam of 60 questions and practical examinations with application of 160 micron in a two-layer system.