Metalizing

Metalizing is a substitute for painting structural steel for decades longer than paint alone. This is a proven process, which has been used around the world for 90 years. One single metalized coating protects steel for 30 to 50 years depending upon the application coating thickness and sealing. Normal paint system last for 10 to 15 years.

How does it work?

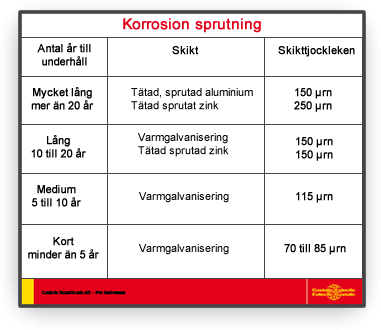

Metallizing is considered a cold process in that the aluminum or zinc is deposited onto steel by spraying, rather than by dipping the steel into a bath of molten zinc as with galvanizing.

The metalizing process always begins with propes surface preparation sa 2,5. Next aluminium and zink or zink wire is melted in an elektric arc spray or gas flame spray gun. Clean compressed airstrips droplets of molten metal from the wire depositing these particles onto the steel forming the protective coating. This sprayed metal coating is both a barrier coating and galvanic coating in one.

The coating that saves you money and time

The cost for metalizing varies with the project. In general an owner can expect to pay about 30 to 40 percent more for a metalized coating than for painting, but the maintenance on board during the next decades will decrease considerably.

Any steel structure that can be blast cleaned we can metalize

Applications include:

- Ships and vessels

- Bridges

- Piers and shore facilities

- Lock and dam gates

- Pipelines

- Offshore oil platforms

- Communication or power transmission poles

Branch in Turkey

In our branch workshop in Istanbul, Turkey, we have facilities in place to help shipyards with metallization, mainly fishing boats to the North. Any metallization which is carried out in Turkey is inspected by our FROSIO inspector on site, which also documents the work. We perform very priceworthy metallizations in Turkey, last project was the bunker boat Pallas built in the Akdeniz Shipyard in Adana. See also www.akdenizshipyard.com